It’s an image familiar to anyone who follows the financial news: Wall Street traders are pictured sitting in front of a multi-screen display with real-time data from a variety of sources, all of which help them decide how and where to place their bets.

Similar technologies are now also available to everyday car buyers. Websites collect data from multiple sources and present users with intelligence on good pricing. They also allow buyers to interact with multiple dealers quickly to secure the desired vehicle at an advantageous price and eliminate hours of showroom haggling.

This technology may be changing the game for supply chain sourcing professionals, putting them in a position to streamline processes, mitigate supply disruptions, save money and significantly add to their top and bottom lines.

And yet, a 2019 survey of a diverse array of manufacturing firms showed that most sourcing teams still rely on the same analog systems and processes they’ve been using for over 20 years: individual category managers with spreadsheets. With a small but growing number of companies adopting supply chain management technologies that process millions of data points affecting supply chains, most of these firms now face the risk of being outmaneuvered by competitors.

Old-school procurement is highly transactional and heavily reliant on relationship management, general business acumen and subject-matter expertise. What that approach lacks are the insights that can be drawn from the massive volumes of supply chain data — the same data that today’s AI technologies can gather, analyze and present to professionals to support decision-making. Instead, these teams typically rely on manually compiled and tediously prepared spreadsheet data, BI tools and fragmented market intelligence reports, which are often old and obsolete by the time they’re considered.

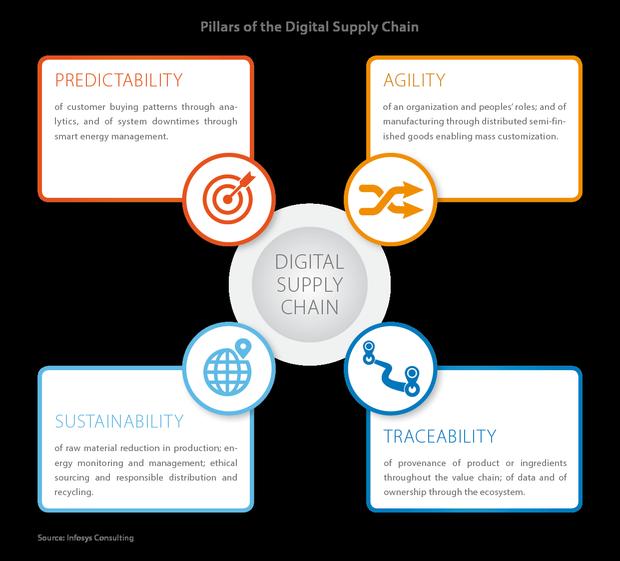

If the COVID-19 pandemic taught supply chain professionals anything, it’s that disruptions are normal. If it’s not a port congestion issue or nuclear disaster, it’s an erupting volcano or a country in lockdown. To navigate these choppy waters, organizations need top-to-bottom supply chain visibility, as well as the ability to make sourcing decisions dynamically. When one considers the successes and failures companies have experienced during the ongoing pandemic, it becomes clear that harnessing these capabilities supports incidental transactions, as well as the strategic position of businesses. For example, consider the automakers that foresaw the current microchip shortage and acted on that insight — and those that didn’t, resulting in market share shifts.

Given today’s realities, procurement efficiencies undoubtedly have a positive impact on companies at a strategic level. A company’s ability to innovate quickly and shorten time to market by making better supplier and part choices will boost its top-line sales. Strategic sourcing and effective procurement negotiations ensure manufacturing enterprises minimize supply chain risks and get the best prices and supply for their inputs — lowering costs and risks proactively and thereby maximizing profits.

To exploit the strategic advantages that procurement can offer, companies must get a handle on the increasing volume and velocity of data coming their way. Manufacturing companies that track the status of thousands of parts need to understand the implications of supply chain data. Once this data is analyzed, it should inform decisions on whether any supply chain adjustments are needed. And, importantly, organizations need information and insights, not just about the present, but also about the future, so they can take proactive measures to secure their positions. It’s impossible to do that by reading spreadsheets and stale reports.

Today’s AI technologies aid in these quests by gathering signals from global media and market sources and then integrating them with internal data to derive insights directly relevant to the company’s business. Technology that didn’t exist a generation ago is now capable of cleansing and enriching that data to detect patterns, ensure its accuracy and reveal contextualized insights. Data from third parties, including information scraped from public sites, is integrated into a solution at scale and at the right velocity — and then meaningfully tied to internal company data.

Dashboards found within these technologies guide sourcing professionals with recommended actions, such as analyzing the risks associated with specific commodities and suppliers or updating the prices of raw materials and parts. A further layer of technology allows procurement professionals to communicate quickly with an entire supply base, thereby slashing the negotiation timeline from weeks or months to minutes.

Taken together, these supply chain management technologies offer companies several strategic advantages. First is the value generated by top- and bottom-line performance improvements. With potential disruptions lurking around every corner, supply chain professionals must work proactively to secure materials and get products out the door. One study showed that companies that implemented advanced procurement technologies garnered gross margin improvements of two to three times the generated cost savings.

A second benefit involves driving internal efficiencies within organizations by cutting time spent on negotiation preparations and bid analysis by as much as 80%. Today’s technologies liberate procurement teams from doing strictly transactional work. Instead, they allow professionals to manage an array of suppliers in depth, resulting in improved overall supply chain performance.

Finally, deploying these capabilities spurs improved innovation processes and faster times to market. One study showed that these efforts increased sourcing velocity by 20% and productivity by a whopping 500%. By better understanding the marketplace and the risks associated with specific suppliers and manufacturing inputs, organizations can make better choices regarding procurement and pricing. The insights and decision support offered by these capabilities also support the development of all-important Plan Bs, so enterprises don’t get caught short when inevitable supply chain disruptions occur.

Today’s environment provides an opening for companies to effect transformational change to their sourcing and supply management operations by implementing these capabilities. The age of strategic sourcing is upon us, and companies that don’t go full frontal on this opportunity risk getting left behind.

Rajesh Kalidindi is founder and CEO of LevaData.